Views: 0 Author: Site Editor Publish Time: 2025-08-05 Origin: Site

Corrosion in stainless steel pipe happens when the protective chromium oxide layer gets damaged. This makes the metal weaker as time goes on. Stainless steel pipes can handle tough conditions, but about 45% of problems in chemical places are from corrosion and cracking. Knowing how corrosion affects stainless steel pipe helps companies pick the best pipes for their needs. It also helps them keep the pipes working well for a long time.

Stainless steel pipes last longer and need less fixing. This helps the environment and cuts down on waste in factories.

Corrosion starts when the chromium oxide layer on stainless steel pipes breaks. This makes the metal get weaker as time goes on.

There are many types of corrosion. These include pitting, crevice, intergranular, stress cracking, and galvanic corrosion. Each type harms pipes in its own way. Each one needs special care.

Picking the right stainless steel grade helps protect pipes from corrosion. Using coatings also helps, especially in places with lots of chlorides or heat.

Checking pipes often and cleaning them gently keeps them strong. This helps find damage early and keeps the protective layer safe.

Stainless steel pipes help the planet by making less waste. They also help green energy projects, especially when made from recycled materials.

Corrosion is when stainless steel pipes get weaker and lose shape. This happens because of chemical or electrochemical reactions with things around them. The metal reacts with water, air, or chemicals. Stainless steel pipes have a thin chromium oxide layer on top. This layer keeps the pipe safe from bad reactions. If this layer gets damaged, the metal under it is not protected. Then, the pipe starts to break down.

Scientists say corrosion is a reaction that makes metal break apart over time. There are different ways this can happen. Uniform corrosion spreads across the whole surface. Pitting corrosion makes tiny holes in the pipe. Intergranular corrosion attacks the metal along its grain lines. Stress corrosion cracking causes cracks when the pipe faces stress and a tough environment. The table below lists the most common types of corrosion in stainless steel pipes:

| Common Forms of Corrosion in Stainless Steel Pipes | Description |

|---|---|

| Uniform Corrosion | General corrosion affecting the entire surface uniformly |

| Pitting Corrosion | Localized corrosion causing small pits or holes |

| Intergranular Corrosion | Corrosion along grain boundaries weakening the metal |

| Stress Corrosion Cracking (SCC) | Cracking due to combined tensile stress and corrosive environment |

Corrosion in stainless steel pipes happens for many reasons. The main reason is the loss of the protective oxide layer. This can happen when strong ions like chlorides or sulfates are in water or chemicals. These ions attack the oxide layer and make corrosion more likely. Still water can also cause uneven oxygen levels. This makes some parts of the pipe corrode faster.

Welded joints in pipes can be weak spots. The heat from welding changes the metal and makes it less strong against corrosion. High heat and moisture make corrosion happen faster. In water treatment, strong ions and long exposure to water can hurt the protective film. This leads to pitting, crevice corrosion, and intergranular corrosion.

Microbes can also help cause corrosion. New studies show bacteria can speed up corrosion, especially in 316 stainless steel pipes. Microbes make substances that change the pipe’s surface. This leads to more corrosion and faster pipe damage.

Tip: Check pipes often and pick the right stainless steel grade. This helps keep pipes strong and lasting longer in tough places.

Stainless steel pipes are good at fighting corrosion. But, different kinds of corrosion can still hurt them. Each kind has its own cause and effect. Knowing about these helps people pick the best pipe. It also helps keep systems working for a long time.

Pitting corrosion makes tiny, deep holes in stainless steel pipes. These holes start where the protective layer is weak. Chlorides, acids, and heat make pitting worse. Water treatment places see pitting a lot, especially in 316 stainless steel pipes. Pipes before fittings and valves are at higher risk. They have more surface area exposed. Pitting is hard to see early because the holes are very small. But, the holes can get bigger fast and cause leaks.

Pitting corrosion happens in small spots and is very harmful.

The first pits are tiny and hard to find.

Places with chloride make pitting more likely, especially for 316 stainless steel pipes.

Pipes with big open areas and tight spaces under clamps get more pitting.

Pitting can happen from 0°C to 30°C, which is common in water treatment.

Note: Check pipes often to find pitting before it gets bad. Picking stainless steel pipes that fight chlorides better can help.

Crevice corrosion happens in small spaces or joints where liquid gets stuck. Oxygen drops inside these spaces. This makes the protective layer weaker. Shallow pits form and corrosion gets faster. The trapped liquid turns acidic as iron ions build up. Chloride ions also gather there. Crevice corrosion shows up under bolts, gaskets, and welds.

Tight spaces lower oxygen and weaken the protective layer.

Iron and chloride ions make the liquid acidic and harmful.

Lots of chloride, high heat, and low pH make crevice corrosion worse.

Still liquid in gaps breaks down the pipe’s protection.

Welds, joints, and under clamps are common places for crevice corrosion.

Designers can stop crevice corrosion by sealing joints and using strong gaskets. Making sure pipes drain well also helps. Lowering heat and chloride levels protects pipes too.

Tip: Removing gaps and using gaskets that do not soak up water helps keep pipes safe.

Intergranular corrosion attacks stainless steel pipes along their grain lines. It starts when chromium carbide forms at these lines. This is called sensitization. Chromium near the grain lines gets used up. This makes those spots weaker against corrosion. The weak spots can break apart and cause cracks.

Chromium carbide forms at grain lines and causes sensitization.

Losing chromium makes grain lines less safe from corrosion.

Corrosion attacks these spots and can split the pipe.

Pipes can lose thickness and get cracks.

Intergranular corrosion is hard to see and needs lab tests.

If not stopped, intergranular corrosion can make pipes fail badly. Using the right heat treatment and picking good materials helps stop this problem.

Note: Stainless steel pipes with less carbon or special grades lower the risk of intergranular corrosion.

Stress corrosion cracking (SCC) happens when stress and a bad environment make cracks in pipes. Chlorides, high heat, and leftover stress from welding or bending make SCC worse. Chemical plants see this problem a lot, especially with 304 or 316 stainless steel pipes.

Chlorides from seawater or cleaners make SCC more likely.

Stress from welding, bending, or pulling helps cracks form.

High heat and wet air above 140°F (60°C) make SCC faster.

Picking the wrong pipe, like austenitic grades in high-chloride places, makes SCC worse.

SCC needs three things: stress, bad chemicals, and high heat.

Leftover stress from making pipes is as bad as stress from use.

Wet air and bad heat treatment also help SCC happen.

To stop SCC, use pipes that fight SCC, lower leftover stress, keep away chlorides, and control heat and pH.

Tip: Duplex and ferritic stainless steel pipes fight SCC better than austenitic grades.

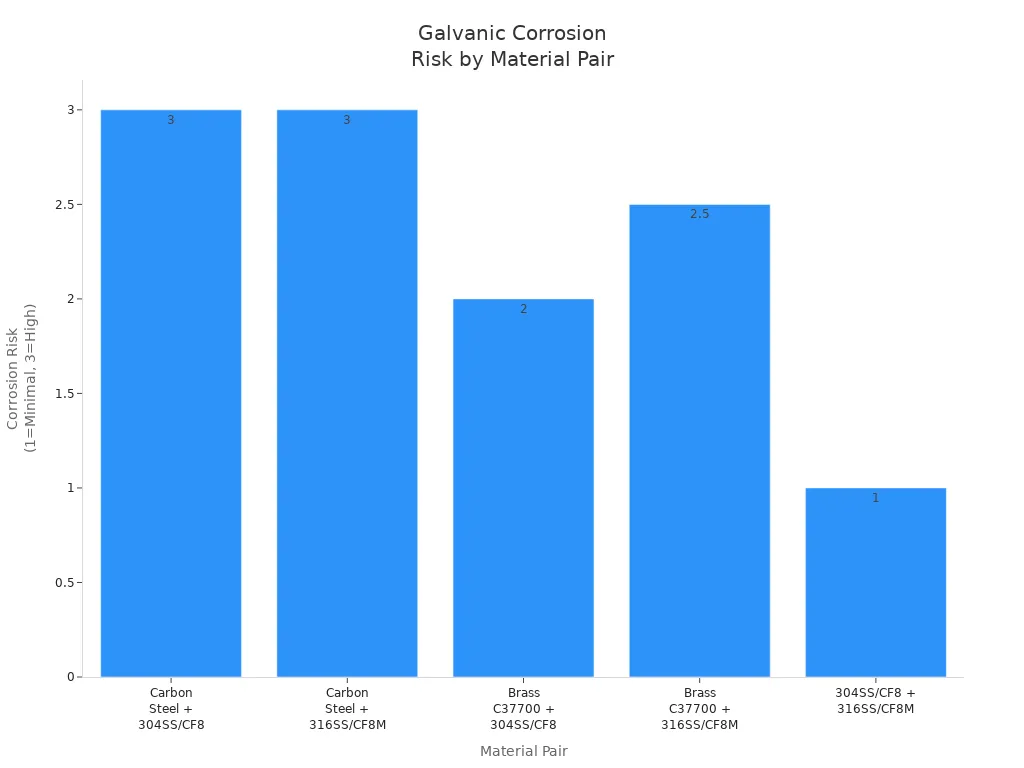

Galvanic corrosion happens when stainless steel pipes touch other metals and water is present. The less noble metal rusts faster. The more noble metal stays safe. This problem shows up at threaded and flanged joints where different metals and water meet.

| Material Pair | Corrosion Risk Level | Explanation |

|---|---|---|

| Carbon Steel + 304SS/CF8 | High | Carbon steel rusts fast when joined with stainless steel. |

| Carbon Steel + 316SS/CF8M | High | 316SS is more noble, so carbon steel rusts even faster. |

| Brass C37700 + 304SS/CF8 | Low–Moderate | Usually fine inside, but risk goes up with water or salt. |

| Brass C37700 + 316SS/CF8M | Moderate | Needs protection in places near the sea to stop rust. |

| 304SS/CF8 + 316SS/CF8M | Minimal | These stainless steels work well together and rarely rust. |

Things like wet air, salt spray, and water help galvanic corrosion happen. Using electrical isolation, coatings, and picking the right metals lowers risk. Choosing metals close together in the galvanic series helps stop corrosion.

Note: Using special unions or insulation at joints helps keep pipes safe when mixing metals.

Stainless steel pipes are strong against many kinds of corrosion. But, each kind needs care. Checking pipes often, picking good materials, and smart design help pipes last longer.

Chemicals are a big reason why stainless steel pipes corrode. Oxygen and other things in water touch the metal surface. Fast-moving water makes this happen more quickly. This movement changes the chemicals around the pipe. It makes corrosion go faster. Chlorides from saltwater and cleaners hurt the chromium oxide layer. Manganese sulfide can start pitting corrosion. Hot nitrate salt vapors make weak oxide layers. These layers fall off and show the metal below. The pH and heat of water also matter. They change how well the protective layer works. Keeping water safe helps lower these risks.

Tip: Keeping the chromium oxide layer safe stops many types of corrosion in stainless steel pipes.

Things like heat and wet air affect stainless steel pipes a lot. High heat makes corrosion happen faster. If the temperature goes up by 10°C, corrosion can double. Humidity keeps water on the pipe. This water helps corrosion start. Near the sea, heat and wet air change a lot. This puts stress on pipes and keeps them wet. Dew and water drops form films that attack the metal. When humidity is over 60%, corrosion in the air is more likely. This is worse if there are pollutants.

Wet air keeps pipes damp and speeds up corrosion.

Heat changes make pipes expand and shrink, which weakens them.

Living near the sea makes corrosion more likely for stainless steel pipes.

The type and quality of stainless steel pipes decide how well they fight corrosion. Grades like 304 and 316 have lots of chromium and nickel. These help stop rust. 316 stainless steel has molybdenum. This makes it better for places with lots of chlorides. Lower carbon grades like 316L are easier to weld. They also lower the chance of corrosion near welds. Picking the right grade and making sure pipes are made well helps them last longer.

| Stainless Steel Grade | Key Feature | Corrosion Resistance |

|---|---|---|

| 304 | High chromium, nickel | Good |

| 316 | Adds molybdenum | Excellent |

| 316L | Lower carbon | Best for welding |

Taking care of stainless steel pipes keeps them strong and safe. Cleaning with water and soft cloths removes dirt. This does not scratch the pipe. Do not use bleach or strong chemicals. These can hurt the protective layer. Check pipes every month by looking at them. Get a professional to check them once a year. In tough places, check every six months. Use coatings and install pipes with good supports. This helps stop corrosion.

Cleaning and checking pipes stops dirt and protects them.

Soft cleaners keep the pipe safe.

Finding damage early stops bigger problems.

Installing pipes the right way lowers the risk of corrosion and damage.

Note: Good care and proper installation help stainless steel pipes last longer, even in tough places.

Car makers use stainless steel pipes in exhausts, frames, and chassis. These pipes fight rust and handle high heat. They also help make cars lighter. Lighter cars use less fuel and last longer. Laser welding and hydroforming make pipes strong and light. Smart pipes in cars check emissions and how well the car works. This helps meet new rules in 2025.

Pipes in exhausts stop rust and handle heat.

Frames and chassis use pipes for crash safety.

New ways to make pipes improve their quality.

Oil and gas companies use stainless steel pipes on platforms and in refineries. Pipes face saltwater, acids, and high pressure. Engineers pick grades like 304, 316, and duplex for their strong oxide layers. Special coatings help pipes fight cracks and pits. Smart systems watch pipes and stop leaks. This is important for hydrogen and green energy.

Stainless steel pipes help build strong bridges and buildings. Rules like ASTM A269 and ASME SB677 make sure pipes fight rust and stay safe. Builders use pressure pipes for water, fire, and air systems. These pipes last long and need little fixing. This makes them good for smart and green buildings.

| Standard | Focus Area | Contribution to Corrosion Resistance |

|---|---|---|

| ASTM A269 | General corrosion service | Makes sure pipes are strong and thick |

| ASME SB677 | Extreme environments | Stops pits and cracks in tough places |

Water pipes made of stainless steel keep water clean and move waste. These pipes do not rust or scale, even when water changes. Smart pipes help find leaks and keep water safe. Stainless steel pipes work for city and factory water needs.

Chemical plants use stainless steel pipes to fight acids and chlorides. Grades like 316, 317, and 904L stop pits and handle heat. Duplex pipes are extra strong for tough places. Smart tools watch pipes and help stop problems.

Food factories use stainless steel pipes to stay clean and stop rust. Smooth pipes keep out germs and biofilm. Grades 304 and 316 are common, but 316 is best for salty foods. Pipes must handle cleaning and heat without breaking.

Medicine and drug places need stainless steel pipes that meet strict rules. Grade 316L fights rust from cleaners and body fluids. Smooth pipes stop germs and keep things pure. Pipes must handle cleaning and keep products safe.

Power plants use stainless steel pipes for steam, cooling, and hydrogen. High heat and chemicals can cause rust and leaks. Germs can make pits and holes in pipes. Smart tools and water cleaning help pipes last in green energy plants.

Heating and fire systems use stainless steel pipes for strength and rust resistance. Special joints and gaskets stop leaks. Pipes do not rust in wet places, so they work well in emergencies. Smart sensors help keep these systems safe.

Note: New trends include duplex grades, smart pipes, and green materials. These help stainless steel pipes work better in renewable energy and hydrogen plants.

Checking pipes often keeps them safe and strong. Smart tools like Eddy Current Array (ECA) find pits and cracks fast. ECA works quicker than radiography and is safer to use. Inspectors can use ECA on painted pipes with little prep. If pipes have insulation, take off the cover first. Then use Eddy Current or Liquid Dye Penetrant Inspection to find hidden corrosion. Infrared Thermography and Neutron Backscatter show damp spots. These spots can be where corrosion starts. Using these tools together gives better results and protects pipes.

Picking the right stainless steel grade helps stop corrosion. Each grade works best in certain places. Ferritic types resist corrosion in low-chloride spots. Austenitic grades like 304 and 316 handle heat and wet air well. Duplex grades are strong and resist corrosion. They work well for hydrogen and green energy systems. The table below shows how each grade works best:

| Stainless Steel Type | Corrosion Resistance | Best Use |

|---|---|---|

| Ferritic | Good | Low-chloride, low-stress areas |

| Austenitic | Very Good | Food, marine, chemical plants |

| Duplex | Excellent | High stress, hydrogen, green energy |

Coatings give extra protection to pipes. Epoxy, polyurethane, and fluoropolymer coatings like PTFE or PVDF keep out water and chemicals. Ceramic and glass coatings also help in tough places. In wastewater or chemical plants, thick epoxy or PTFE linings stop acids. This keeps pipes safe. Good prep and picking the right coating help pipes last longer.

Cleaning pipes the right way keeps them strong. Use soft cloths and wipe along the polish lines. Pick cleaners without chlorides or strong acids. Keep pipes dry and clean to stop moisture. After welding, clean and passivate the area to make it strong again. Insulate pipes to keep out water and control heat changes. Check pipes often and clean gently to stop corrosion.

Green manufacturing is growing in 2025. About 80% of new stainless steel pipe uses recycled metal. Factories use renewable energy and smart ways to cut waste. Many companies get eco-friendly certificates. They use local suppliers and control raw materials to help the planet. These green steps help stainless steel pipe support hydrogen and green energy projects and protect nature.

Stainless steel pipes can get different kinds of corrosion. These include pitting, crevice, and galvanic corrosion. Each kind happens for a different reason. Chloride ions or touching other metals can cause problems. Checking pipes often helps stop damage. Picking the right pipe material also helps keep pipes safe. Making pipes in a green way is more important now. People should know new ways to stop corrosion. They should learn the best tips for every use.

| Corrosion Type | Causes | Prevention Strategies |

|---|---|---|

| Pitting | Chloride ions, weak passivation | Use resistant grades, apply coatings |

| Galvanic | Dissimilar metals, electrolytes | Isolate metals, use protective layers |

| Crevice | Oxygen depletion in joints | Welded joints, avoid crevices |

Corrosion starts when the chromium oxide layer breaks. Chloride ions, high heat, and bad care make it weak. Pipes in tough places need checks to stay strong.

Pick the right stainless steel grade and use coatings. Clean pipes often to keep them safe. Keep pipes dry and away from chlorides to stop pitting.

| Industry | Main Use |

|---|---|

| Oil & Gas | Moving fluids |

| Food & Beverage | Clean water systems |

| Construction | Building frames |

| Chemical Plants | Handling strong fluids |

Stainless steel pipe does not rust as fast as regular steel. It can still rust if the protective layer is hurt. Checking and cleaning pipes helps stop rust.

316 stainless steel pipe is best for saltwater. It has molybdenum for extra protection from chloride corrosion. Many marine and chemical places use 316 for this reason.