Views: 0 Author: Site Editor Publish Time: 2025-08-14 Origin: Site

Selecting the right stainless steel pipe is important. It helps buyers and users a lot. The right pipe type and grade fit the environment. This can lower costs over time. It also makes the pipe work better. Stainless steel pipe can last up to 100 years if chosen well. This is true in factories and other tough places. Buyers look at seamless pipes for strength and long life. Welded pipes are good for easier jobs. There are many types like austenitic, ferritic, martensitic, duplex, and precipitation hardened. Grades include 304, 316, and low carbon choices. Picking carefully means less fixing, less upkeep, and better results.

Pick the right stainless steel pipe type and grade. This helps pipes last long, stay strong, and not rust. Austenitic pipes work best for hard jobs. They resist rust well and are easy to weld. Ferritic pipes cost less and handle heat well. Grades 304 and 316 are used a lot. Grade 304 is good for most uses. Grade 316 is better for salty or chemical places. Low carbon grades like 304L and 316L help welding. They also lower rust after welding. Always choose pipes that fit the job’s place, pressure, and heat. This saves money and stops expensive fixes.

Stainless steel pipe comes in different types. Each type has special features and uses. Knowing about these types helps buyers pick the right pipe. The main types are austenitic, ferritic, martensitic, duplex, and precipitation hardening stainless steel pipe. Each one works best in certain places and jobs.

Austenitic stainless steel pipe is the most common type. It includes the 200 and 300 series. Its structure is called face-centered cubic. Nickel or manganese keeps this structure stable. This makes the pipes non-magnetic when annealed. Chromium and nickel make a layer that protects the pipe. This layer stops rust in acid, base, and salty places. If molybdenum is added, it helps stop pitting from salt.

Austenitic stainless steel pipes are strong and bend easily. They do not crack when shaped. Welders like these pipes because they weld well and stay strong. These pipes keep their strength in hot and harsh chemical places.

Tip: Use austenitic stainless steel pipe where rust is a big problem. It is also good for hot or chemical-heavy places.

Many industries use austenitic stainless steel pipes:

Chemical plants use them to move harsh liquids.

Oil and gas companies use them in refineries and pipelines.

Food and drink factories need pipes that are clean and easy to wash.

Water treatment plants use them because they handle chlorine and chemicals.

Builders use them for strong and weather-proof structures.

Car makers use them in exhausts and fuel lines for heat and strength.

Medical equipment makers use them because they resist rust and are easy to clean.

Austenitic stainless steel pipe is the top pick for tough jobs. It is strong, resists rust, and is easy to weld.

Ferritic stainless steel pipe has a body-centered cubic structure. These pipes have iron and chromium, but no nickel. Chromium is usually between 12% and 30%. Because there is no nickel, these pipes cost less than austenitic ones. Ferritic pipes are magnetic. They have higher yield strength but lower tensile strength than austenitic pipes.

| Characteristic | Ferritic Stainless Steel | Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) | Body-Centered Tetragonal |

| Major Alloying Elements | Iron, Chromium (12%-30%), no Nickel | Iron, Chromium, Nickel (8-10%) | Iron, Chromium, Carbon |

| Magnetic Properties | Magnetic | Non-magnetic | Magnetic |

| Corrosion Resistance | Good, reduced by carbides | Excellent | Moderate |

| Mechanical Properties | Higher yield, lower tensile strength | Higher tensile, lower yield strength | High hardness and strength |

| Cost | Lower | Higher | Moderate |

| Formability | Poorer | Excellent | Moderate |

Ferritic stainless steel pipes do not crack easily in salty places. They are easy to shape and form. Their heat moves well, so they are good for heat exchangers, furnaces, and boilers.

People use ferritic stainless steel pipe for many things:

Car exhausts, because they need to handle heat and rust.

Home appliances, like washing machines and water heaters.

Building parts, such as facades and handrails.

Petrochemical equipment, where pipes face pressure and harsh liquids.

Food processing, where pipes must stay clean and not rust.

Marine jobs, where special ferritic pipes handle saltwater and heat.

Ferritic stainless steel pipe is a cheaper choice for many jobs. It is magnetic, resists rust, and handles heat well.

Martensitic stainless steel pipes have a body-centered tetragonal structure. They have chromium, usually 12-13.5%, and carbon. Carbon makes them stronger and harder. These pipes can be heat-treated to get even stronger. They resist some rust and heat up to about 535°C (1000°F).

Martensitic stainless steel pipes are best when strength matters more than rust resistance. They are magnetic and easy to machine and shape. Welders must use the right steps to stop cracks and control hardness.

Martensitic stainless steel pipes are used in many ways:

Fasteners, springs, and pins

Knives and hardware

Gun clips and small parts

Turbine blades and coal screens

Pump rods, nuts, bolts, and fittings

Ball bearings, shafts, impellers, and pistons

Valves and valve trim

Surgical tools and guns

These pipes are very strong and hard. They work well in tough jobs. They can handle some chemicals, but not too many.

Duplex stainless steel pipe mixes the best parts of austenitic and ferritic types. Its structure is half austenite and half ferrite. This gives duplex pipes more strength and better rust resistance, especially against salty water and pitting.

| Property/Aspect | Duplex Stainless Steel | Austenitic Stainless Steel (Type 304) |

|---|---|---|

| Microstructure | Equal parts austenite (FCC) and ferrite (BCC) | Primarily austenitic (FCC) |

| Chromium Content | 20–28% | Lower than duplex |

| Molybdenum Content | Up to 5% | Lower or absent |

| Nickel Content | Up to 9% (lower than austenitic) | Higher (~8-10%) |

| Nitrogen Content | 0.05–0.50% | Typically lower |

| Strength (0.2% proof) | 450–550 MPa | ~280 MPa |

| Corrosion Resistance | Superior to austenitic | Good, but less than duplex |

Duplex stainless steel pipes do not crack in salty or sulfide places. They are strong, so thinner pipes can be used, saving money. They also handle repeated stress well.

Industries use duplex stainless steel pipe for:

Oil and gas, for pipes and platforms in the sea.

Chemical plants, where pipes face harsh chemicals.

Marine jobs, like shipbuilding and water plants.

Water treatment, where pipes must handle chlorine and pressure.

Note: Duplex stainless steel pipe lasts longer and needs less fixing in tough places.

Duplex stainless steel pipes are strong, resist rust, and weld well. They are a top pick for tough and important jobs.

Precipitation hardening stainless steel pipe goes through special heat treatment. This makes tiny particles inside the metal. These particles make the pipe stronger and harder. The pipes still resist rust and keep their shape. Annealing makes them softer, easier to shape, and improves their structure.

| Step | Description |

|---|---|

| Solution Annealing | Heating to dissolve alloying elements into the matrix. |

| Quenching | Rapid cooling to trap elements in solid solution. |

| Aging (Precipitation Treatment) | Reheating to form fine precipitates that block dislocation motion. |

| Key Alloying Elements | Role |

|---|---|

| Copper (Cu) | Helps with aging treatment |

| Aluminum (Al) | Makes small particles during aging |

| Niobium (Nb)/Titanium (Ti) | Controls grain size and how particles form |

| Chromium (Cr) | Keeps the pipe from rusting |

| Nickel (Ni) | Keeps the austenitic structure stable |

| Benefits of Precipitation Hardening | Effects on Stainless Steel Pipes |

|---|---|

| Increased strength and hardness | Small particles stop movement, making pipes stronger |

| Good corrosion resistance | Chromium and other elements help stop rust |

| Dimensional stability | Pipes keep their shape and strength over time |

| Machinability and weldability | Easy to machine and weld after annealing |

| Lower distortion during heat treatment | Less bending or warping than martensitic pipes |

Precipitation hardening stainless steel pipes are used where high strength is needed. These pipes are found in planes, cars, ships, and machines. For example:

Oil and gas companies use them for gates, valves, and springs.

Car makers use them for engine parts, gears, and shafts.

Airplane companies use them for plane parts and turbine blades.

Shipbuilders use them in ships and sea platforms.

Machine makers use them for shafts, fasteners, and pressure tanks.

Precipitation hardening stainless steel pipe is strong, bends well, and resists rust. These pipes are great for jobs where strength and rust resistance are both important.

Tip: Precipitation hardening stainless steel pipe is best for places that need both strength and rust resistance.

Picking the right grades of stainless steel pipe is important. Each grade has its own features and chemical makeup. These things change how pipes work in different places. Knowing about grades helps you choose better. It also helps stop problems like rust or cracks.

304 stainless steel pipe is the most used grade. Many industries like it because it resists rust and is flexible. It has about 18-20% chromium and 8-10.5% nickel. This mix makes the pipe strong and keeps it from rusting. It works well in kitchens, food factories, and buildings.

304 stainless steel pipes do not rust easily. They work in places with water, weak acids, and cleaning stuff. Nickel makes them tough and stops cracks. These pipes are not magnetic and are easy to weld. They keep their shape after bending.

Tip: Use ss 304 pipes for jobs that need rust resistance and easy cleaning.

The table below shows how different grades resist rust:

| Stainless Steel Grade | Chromium Content (%) | Nickel Content (%) | Corrosion Resistance Compared to 304 |

|---|---|---|---|

| 303 | ~18 | ~8 | Slightly lower due to sulfur content |

| 304 | 18-19.5 | 8-10.5 | Excellent (baseline) |

| 316 | 16-18 | 10-14 | Better than 304, especially in chloride environments |

| 430 | 16-18 | 0 | Lower than 304, less effective in harsh environments |

304 stainless steel pipes are used for:

Kitchen sinks and counters

Food machines

Chemical containers

Water pipes and fittings

Building parts

These pipes are strong and do not rust in most jobs. They are simple to clean and take care of.

316 stainless steel pipe is great at fighting rust, even in hard places. It is different from 304 because it has 2-3% molybdenum. This helps stop pitting and crevice rust in salty or chemical places. The pipe has 16-18% chromium and 10-14% nickel, plus molybdenum.

Molybdenum in ss 316 pipes helps in salty or chemical jobs. These pipes do not rust or crack in seawater or strong chemicals. Nickel makes them tough and helps them last longer. Less carbon in 316L stops weld decay and rust after welding.

| Element | Typical Content (%) | Contribution to Corrosion Resistance and Properties |

|---|---|---|

| Molybdenum (Mo) | 2% - 3% | Stops pitting and crevice rust, especially in salty places. |

| Nickel (Ni) | 10% - 14% | Makes pipes tough and helps stop rust. |

| Carbon (C) | ≤ 0.03% in 316L, ≤ 0.08% in 316 | Less carbon means less rust after welding, better for welded pipes. |

| Titanium (Ti) | ~0.5% in 316Ti | Stops problems at high heat, helps with rust resistance. |

316 stainless steel pipes are best for:

Marine and beach jobs

Chemical plants

Medicine and food factories

Water cleaning and salt removal plants

Medical tools and clean systems

Note: ss 316 pipes last longer and need less fixing in salty or chemical places.

These pipes are strong and do not rust easily. They work where 304 pipes might not last.

Some jobs need other grades of stainless steel pipes. Each grade has its own special features and rust resistance.

Grade 430 is a ferritic stainless steel pipe. It has 12-18% chromium and little carbon. The pipe is magnetic and gets harder with heat. It resists rust and stress cracks. Grade 430 pipes cost less and work in easy jobs.

Grade 321 is an austenitic stainless steel pipe. It has titanium, which stops problems when welding. This grade bends well and resists rust at hot and cold temperatures. Grade 321 pipes are good for places with big temperature changes.

Grade 410 is a martensitic stainless steel pipe. It has lots of chromium and iron, plus more carbon. This grade is strong, hard, and resists wear. Grade 410 pipes are used for medical tools and jobs that need hard edges.

| Grade | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) | Rockwell Hardness |

|---|---|---|---|---|

| 321 (Annealed) | 90,000 - 105,000 | 35,000 - 75,000 | 55 | RB80 |

| 321 (1/8 Hard) | 90,000 - 105,000 | 35,000 - 75,000 | 20 | RB95 |

| Stainless Steel Grade | Typical Applications |

|---|---|

| 430 (Ferritic) | Chemical equipment, food and wine pipes, home appliances, building parts, oil burner parts, outdoor signs, bolts, nuts, screens, burners |

| 321 (Austenitic) | Hot and cold places, jobs needing bending and rust resistance |

| 410 (Martensitic) | Medical tools, hard edges, jobs needing strength and wear resistance |

Tip: Pick the grade that fits the job. Grade 430 is for easy jobs. Grade 321 is for hot or cold places. Grade 410 is for hard, tough jobs.

These grades have different strengths and rust resistance. Buyers should check what the job needs before picking.

Low carbon grades like 304L and 316L are made for better welding and rust resistance. The 'L' means low carbon. For example, 304L has less carbon than regular 304. Less carbon stops rust after welding.

| Grade | Max Carbon Content | Key Benefit of 'L' Grade |

|---|---|---|

| 304 | 0.08% | Regular carbon |

| 304L | 0.03% | Less rust after welding |

| Suffix | Meaning | Impact on Performance | Typical Use |

|---|---|---|---|

| L | Low Carbon | Stops rust after welding, better for welded pipes | Welded chemical lines, medicine pipes |

Low carbon pipes can be used right after welding. This saves time and money because no extra heating is needed. These pipes resist rust, even in welded places with chemicals or salt.

Less carbon makes welding easier and stops rust. 316L pipes do not pit or crack in salty places. They also resist rust after welding.

Note: Use low carbon pipes for jobs with lots of welding or harsh chemicals.

Low carbon grades cost more, but they are strong and last longer in hard jobs. Buyers should use these grades for chemical plants, medicine factories, and water cleaning systems.

ASTM rules set the standards for stainless steel pipe grades. These rules say what chemicals and tests are needed. ASTM A312 is the most used rule for stainless steel pipes. It covers seamless, welded, and strong pipes for hot and general jobs.

The 'L' in grades like 304L and 316L means low carbon. This helps with welding and stops rust after welding. Pipes with 'L' are used in chemical lines, medicine systems, and places that need to stay clean.

Tip: Always check ASTM rules and the 'L' before buying stainless steel pipes. This makes sure the pipe fits the job and lasts longer.

Knowing about stainless steel pipe grades helps you pick the right one. 304 pipes resist rust and work in easy places. ss 304 pipes are flexible and easy to clean. ss 316 pipes are best for salty or chemical jobs. Other grades like 430, 321, and 410 have special uses. Low carbon grades like 304L and 316L are better after welding. ASTM rules and the 'L' help buyers choose the best pipe. Picking the right grade means strong pipes, long life, and fewer problems.

Stainless steel pipe is used in many places. It works well in different jobs and environments. Picking the right type and grade is important. This helps pipes last longer and work better. Each job needs special things like rust resistance, strength, or heat resistance.

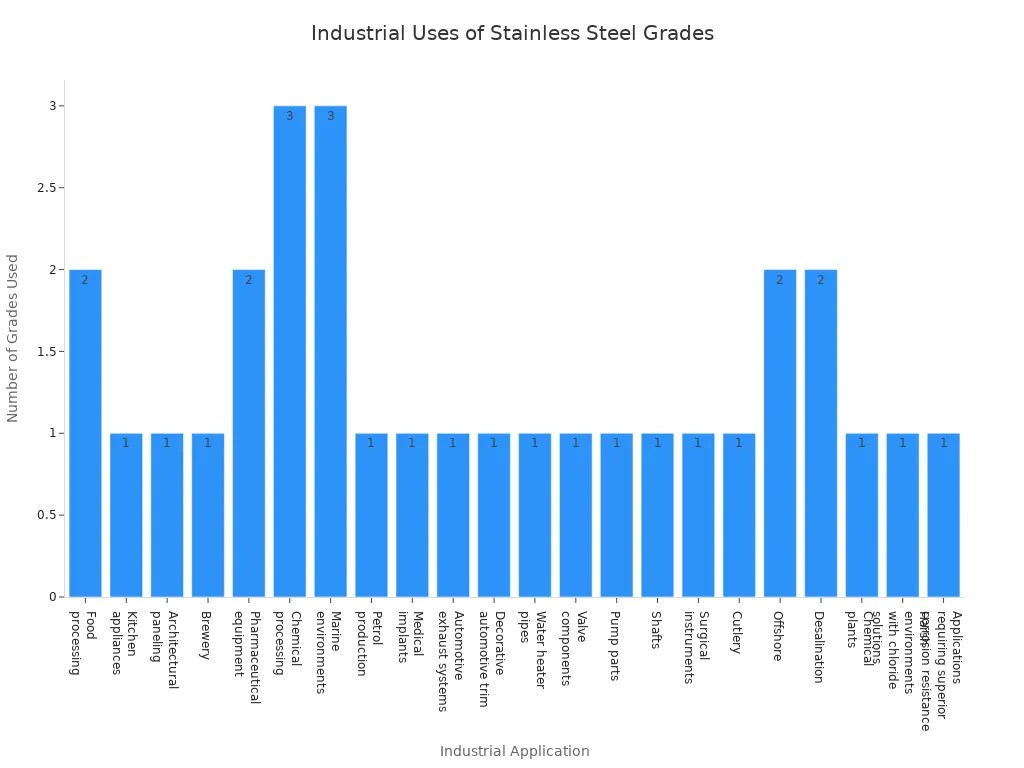

Factories and plants use stainless steel pipe a lot. These pipes move chemicals, water, and gases safely. The right grade stops rust and damage. Grades 304 and 316 are good for food, chemical, and medicine jobs. Duplex grades like UNS S31803 and S32205 are strong in tough places. They work well offshore and in the sea.

| Stainless Steel Grade | Typical Industrial Applications | Key Characteristics |

|---|---|---|

| 304 | Food processing, kitchen appliances, brewery, pharmaceutical equipment | Excellent corrosion resistance, versatile |

| 316 | Chemical processing, marine, medical, petrol production | Superior resistance in chloride environments |

| 409 | Automotive exhaust systems | Good oxidation resistance, economical |

| UNS S32750 | Offshore, chemical plants, desalination | Exceptional resistance, high strength |

Tip: Always pick a pipe that matches the job. This keeps things safe and saves money.

Homes and businesses use stainless steel pipe too. Pipes are used for plumbing, water, and building parts. These pipes do not rust and last a long time. Grade 304 is used in kitchens, bathrooms, and water pipes. Grade 430 is good for trim and water heaters. Stainless steel pipe keeps water clean and safe. It is a smart choice for homes and businesses.

Plumbing systems

Water heaters

Handrails and supports

Kitchen and bathroom fixtures

Some jobs need pipes that can take a lot of heat. Grades 310 and 321 are good for high heat and oxidation. These pipes keep their shape and strength up to 1200°C. They are used in boilers, furnaces, and chemical plants. The right grade stops scaling and keeps things safe.

Key things for high-heat jobs:

Can take heat up to 1300°C

Stops rust and oxidation

Stays strong when hot

Does not expand much

| Grade | Suitable Temperature Range | Key Properties | Typical Applications |

|---|---|---|---|

| 310 | Up to 1200°C | High resistance to heat and oxidation | Boilers, combustion chambers |

| 321 | High temp stability | Good resistance, stable with titanium | Heat exchangers, aerospace |

Note: Always use the right pipe for the heat and chemicals in the job.

Picking the right pipe keeps things safe, makes pipes last longer, and means less fixing.

Picking the right grade of stainless steel pipe is important. Buyers should match the pipe to the job. The place where the pipe will be used matters a lot. Pipes in salty or chemical areas need strong corrosion resistance. Temperature, pH, and stress can change how pipes work.

Buyers should check if the pipe is strong and tough. Some jobs need pipes that hold heavy loads or pressure. The way the pipe is made is important too. If the job needs lots of welding or bending, grades like 304L or 316L are better. These grades help stop problems after welding and keep the pipe strong.

Cost and how easy it is to find the pipe also matter. Some grades cost more but last longer and need less fixing. The look of the pipe, certifications, and rules like ASTM A312 or A249 can help buyers decide. Working with skilled suppliers helps buyers pick the best grade.

| Factor | Description |

|---|---|

| Corrosion Resistance | Austenitic grades (e.g., 316) offer highest resistance due to chromium and molybdenum content. |

| Operating Environment | Temperature, pH, stress, and crevice corrosion affect performance; 304 and 316 are versatile. |

| Strength & Ductility | Chromium and nickel increase strength; grades like 420 offer high tensile strength. |

| Process Temperatures | Consider maximum use temperature and heat treatment compatibility. |

| Weldability & Formability | Lower carbon grades (304L, 316L) reduce weld embrittlement; formability varies by grade. |

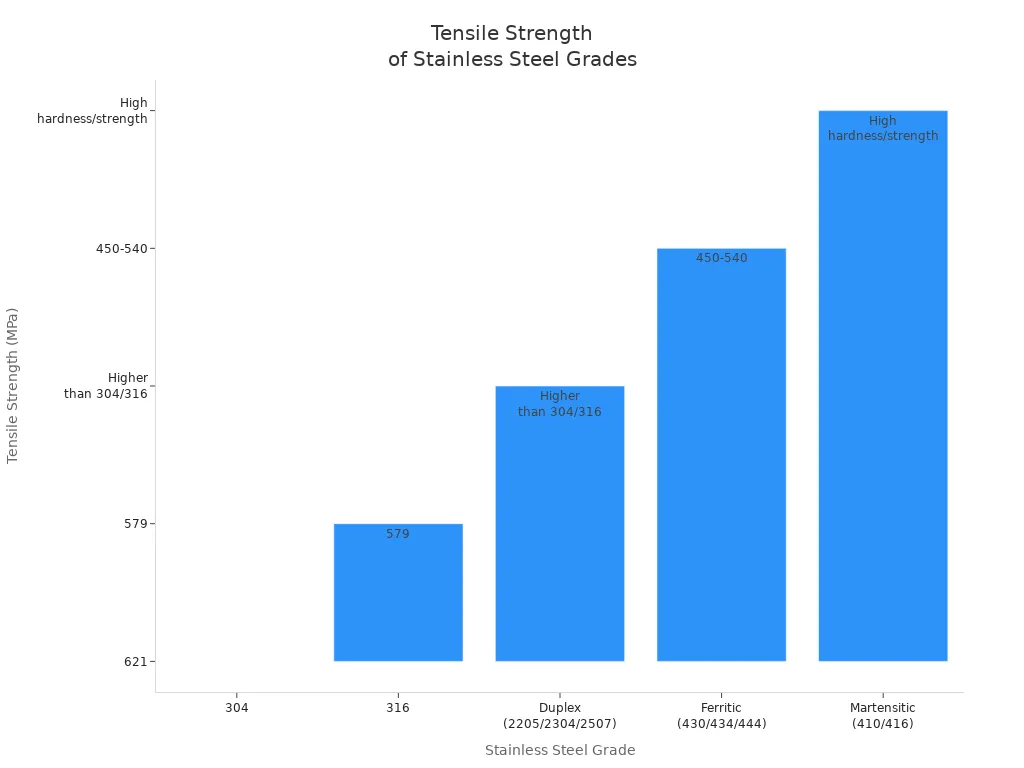

Different grades of stainless steel pipe have special benefits. Austenitic grades like 304 and 316 resist rust well and are easy to weld. Ferritic grades like 430 cost less but are not as strong or resistant. Martensitic grades like 410 are very strong and hard but do not resist rust as much. Duplex grades are strong and resist rust better, so they are good for tough jobs.

| Stainless Steel Grade | Cost Comparison | Corrosion Resistance | Mechanical Strength (Tensile Strength) |

|---|---|---|---|

| 304 | Lower cost | Good general resistance | ~621 MPa (90 ksi) - highest among common grades |

| 316 | Higher cost | Superior resistance, especially in marine environments | ~579 MPa (84 ksi) |

| Duplex (2205, etc.) | More expensive | Better resistance than austenitic | Higher than 304 and 316 |

| Ferritic (430, etc.) | Lower cost | Lower resistance | Lower strength (e.g., 450 MPa for 430) |

| Martensitic (410, etc.) | Moderate to low cost | Lower resistance | High hardness and strength |

Tip: Always think about resistance, strength, weldability, and cost when picking stainless steel pipe grades for each job.

Picking the right stainless steel pipe type and grade is important. It helps pipes last longer and keeps things safe. Buyers need to match the pipe to the job. They should think about pressure, temperature, and where the pipe will be used. If you use the wrong grade, the pipe can rust or break. This can lead to expensive fixes.

Check how well the pipe resists rust, how strong it is, and how it looks for each job

Ask experts or suppliers for advice that fits your needs

Making smart choices saves money and helps things work well in every industry.

Seamless stainless steel pipe has no weld seam. It offers higher strength and better pressure resistance. Welded stainless steel pipe has a visible seam. It costs less and works well for many standard uses.

Buyers should check the job needs. They must consider corrosion, strength, and temperature. Grades like 304 and 316 fit most uses. Duplex and low carbon grades work best for harsh or welded environments.

Stainless steel pipe contains chromium. Chromium forms a thin, invisible layer on the surface. This layer protects the pipe from rust and chemical damage. Higher chromium and nickel content increase resistance.

Yes, stainless steel pipe is safe for drinking water. It does not leach harmful chemicals. It keeps water clean and pure. Many cities and homes use it for plumbing and water supply systems.

The 'L' stands for low carbon. Low carbon stainless steel pipe resists rust after welding. It works well in chemical plants and places with frequent welding. This grade helps prevent corrosion at welded joints.