Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

Black steel pipes have many good points for building projects. They are strong and can handle high pressure. It is easy to change them at the work site. Many builders use them for gas lines and support because they are cheap and flexible. But these pipes do not fight rust well. They need to be checked and fixed often, especially when it is damp. They look rough and cannot be used much with water or harsh chemicals. This limits how they can be used. Stainless steel pipes do not rust as easily. People use them where black steel pipes have problems. Looking at both types helps managers pick the right pipe for each job.

Black steel pipes are very strong. They cost less money. This makes them good for high-pressure jobs. People use them for gas lines and building support. These pipes need regular checks. They need care because they can rust easily. Rust happens more in wet or damp places. Black steel pipes are not good for drinking water systems. This is because they can rust. But they work well for fire sprinklers. They also work well for gas pipelines. Installing black steel pipes takes more work. They are heavy and need special tools. You must handle them carefully. Stainless steel pipes do not rust as much. They need less care but cost more money. Pick pipes based on the job’s needs and the place where you use them.

Black steel pipes are very strong. They work well for building and big projects. These pipes are made by welding or making them seamless. Heat treatment makes them even stronger. Grade B black steel pipes have more carbon and manganese than Grade A. This means Grade B pipes are stronger and can hold more weight. They are good for oil, gas, and energy systems.

Engineers pick black steel pipes for buildings and bridges. These pipes can handle high heat and pressure. They are stiff and tough. This helps them work in hard places like oil refineries and power plants. In plumbing, black steel pipes do not bend easily. They keep their shape when stressed. This makes them last longer and work better.

| Property | Grade A Black Steel Pipe | Grade B Black Steel Pipe |

|---|---|---|

| Carbon Content | Up to 0.25% | Up to 0.30% |

| Manganese Content | 0.95% to 1.44% | 0.29% to 1.06% |

| Tensile Strength | Lower tensile strength | Higher tensile strength |

| Yield Strength | Lower yield strength | Higher yield strength |

| Typical Applications | General structural, low pressure fluid | High-pressure fluid transfer, heavy-load |

| transfer, non-critical industrial uses | structural and mechanical applications |

Tests show Q235 steel black pipes work well under high pressure. Thicker walls make pipes stronger, especially short ones. Designers must think about pipe length, wall thickness, and any flaws. This helps keep projects safe and pipes working right.

Black steel pipes cost less to install and keep up. They are not too expensive per foot. It is not too hard to put them in. This makes them good for homes and businesses. Black steel pipes cost less than copper and stainless steel pipes. This helps builders save money.

| Pipe Material | Installation Cost & Ease | Maintenance Cost & Durability | Notes on 10-Year Cost Impact |

|---|---|---|---|

| Black Steel Pipes | Medium cost per foot; medium ease of installation (threaded fittings require care) | Moderate maintenance due to lack of corrosion resistance | More cost-effective than galvanized steel for gas systems; balance of moderate installation and maintenance costs |

| Copper | Higher initial cost; more labor-intensive installation | Lower maintenance due to durability and corrosion resistance | Higher upfront cost but potential long-term savings due to durability |

| Stainless Steel | High initial cost; complex installation | Very low maintenance due to excellent corrosion resistance | Long lifespan reduces replacement and repair costs over time |

| Galvanized Steel | More labor-intensive and costly installation | Higher maintenance due to corrosion and rust issues | May incur higher maintenance and replacement costs within 10 years |

| PVC, CPVC | Low installation cost due to lightweight and ease of handling | Low maintenance; resistant to damage and corrosion | Lower total cost over 10 years due to low installation and maintenance costs |

| PEX | Very high ease of installation; flexible and lightweight | Very low maintenance; fewer joints reduce leak risk | Low installation and maintenance costs contribute to cost savings over time |

Black steel pipes need some care because they can rust. But they are a good deal for gas lines. Other pipes like galvanized steel may need to be replaced sooner. Over ten years, black steel pipes are a smart choice for many jobs.

Black steel pipes are great for moving gas. They are strong and can bend a little. This helps them handle high pressure in gas lines. The black coating gives some protection from rust. This is important for safety and making pipes last longer. These pipes meet safety rules like NFPA 54 and ASTM A53/A53M. They are used for natural gas pipes above ground.

Black steel pipes are best for gas systems with high pressure.

Welded joints are good for high-pressure jobs.

Threaded joints work for smaller pipes.

Pipes must be grounded to stop sparks and fires.

Painting pipes outside helps stop rust and makes them last longer.

Black steel pipes work well for oil and gas jobs. They help move natural gas and propane safely. They follow the rules, so people trust them for energy projects.

Putting in black steel pipes takes several steps. Workers measure and cut the pipes. They use special tools to smooth the edges. Pipes are joined with sealant and Teflon tape. Workers use threaders and wrenches to make tight connections. After putting pipes together, they test them for leaks.

Black steel pipes are heavy and hard to move.

Sometimes pipes need coatings to stop rust.

Threaded and welded joints can save time and money.

The weight and rust problems can make work harder.

Workers must be careful to avoid damage and make sure pipes fit.

Tip: Project managers should plan for more work and time with black steel pipes. Big projects need extra help and training. The right tools make installation easier and better.

Black steel pipes are still used a lot for oil, gas, and power. They are strong, not too expensive, and work well in tough places. Their installation fits many building and plumbing needs, so they are useful for lots of projects.

Black steel pipes have trouble fighting rust. They do not have a zinc layer to protect them. This makes them rust faster when wet or in soil. The iron oxide coating helps a little, but not much. Rust can start quickly and spread over time. This makes pipes weaker and less reliable.

Where the pipes are used affects how fast they rust. Pipes in soil can rust slowly or very fast. Good soil slows rust to less than 0.2 microns each year. Bad soil can make rust go over 20 microns each year. Microbes, soil pH, and moisture change the rust rate. In factories, pipes can rust up to 0.7 mm each year. Salt and humidity make rust happen faster near the sea or in the air.

| Environment/Condition | Corrosion Rate Range (mm/year) | Notes and Influencing Factors |

|---|---|---|

| Soil (general) | 0.05 to 0.5 | Corrosion rate depends on soil resistivity, pH, moisture, salt content; limestone, sands have lower rates |

| Soil (peat/swamp-like terrain) | Up to 1 | Lower resistivity soils with higher corrosion rates |

| Microbiologically Influenced Corrosion (MIC) | 0.2 to 0.7 (typical), >5 (extreme) | Caused by sulfate-reducing bacteria and acid-producing bacteria; coating disbondment increases risk |

| Pipeline external corrosion | 0.05 to 0.5 | Uniform corrosion typical; localized corrosion can be higher |

New coatings and inhibitors help slow down rust. These solutions cost more and make things harder. Microbial biofilms from bacteria can make rust worse. They form thick layers on the pipe. Black steel pipes rust more than stainless steel pipes. This makes them a bad choice for wet or tough places.

Note: Coatings and inhibitors help slow rust, but cannot stop it. Pipes still need regular checks and repairs.

Black steel pipes are not good for water systems. They rust easily when water touches them. The iron oxide layer does not protect pipes for long. Rust can break off inside the pipe. This can make water dirty and unsafe to drink.

Black steel pipes can make water systems last less time.

Rust and corrosion can cause leaks and block water flow.

Drinking water can get iron oxide and other rust bits.

Black steel pipes work better for fire sprinklers or factory water, not for drinking.

Cities using black steel pipes often have problems. Rust builds up inside pipes and causes leaks. Bacteria can make rust worse and break pipes. These problems cost more money and make water systems work less well.

Tip: For water supply, use galvanized steel, copper, PEX, or PVC. These pipes fight rust better and keep water safe.

Black steel pipes need more care than other pipes. Workers must check for leaks and rust often. Many places fix leaks every few months. Rusty pipes may need to be replaced in five to ten years. This makes owning these pipes cost more.

A medium facility can spend $1,500-$3,000 each year on care.

Repairs need special workers, which makes things harder.

Fixing pipes can stop gas or water and slow work.

Black steel pipes are easier to fix than stainless steel pipes, but need more repairs.

Stainless steel pipes fight rust better and need less care. Black steel pipes are easier to fix because they bend more. But needing lots of repairs makes them less strong over time.

Black steel pipes weigh more than PVC or aluminum pipes. Their heavy weight makes moving and installing them harder. Big projects need more workers and special tools. This can cost more money and take longer.

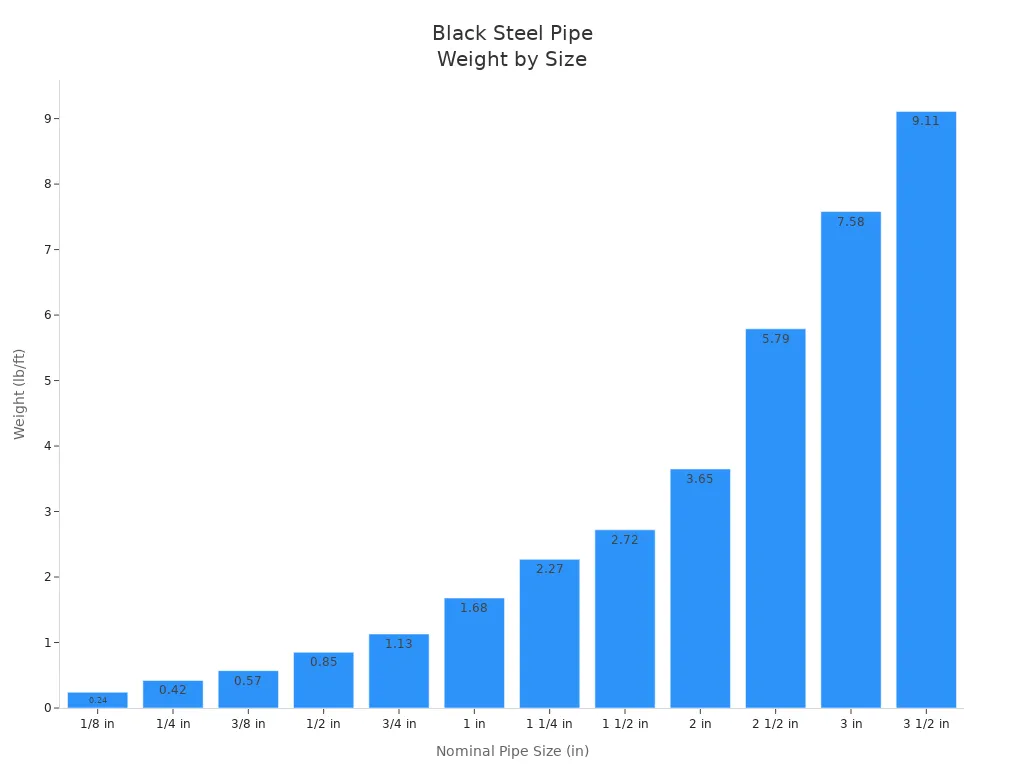

| Nominal Pipe Size (in) | Outside Diameter (in) | Wall Thickness (in) | Weight (lb/ft) |

|---|---|---|---|

| 1/2 | 0.840 | 0.11 | 0.85 |

| 1 | 1.315 | 0.13 | 1.68 |

| 2 | 2.375 | 0.15 | 3.65 |

| 3 | 3.500 | 0.22 | 7.58 |

| 3 1/2 | 4.000 | 0.23 | 9.11 |

Heavy pipes need strong supports like brackets or hangers. This stops them from sagging or breaking. Their weight and stiffness make bending hard. Workers must cut or weld pipes to fit. These things slow down work and cost more money.

Callout: Project managers should plan for more help and time when using black steel pipes. Lighter pipes are easier to move and install.

When picking black steel pipes, you need to think about many things. Builders like black steel pipes because they are strong and save money. These pipes work well when pressure is high. They do not bend or crack easily. The black coating helps stop rust, so pipes can be used outside. But there are some problems too. The coating can come off and let the pipe rust. Heavy pipes cost more to move and install. The inside of the pipe is rough, so water or gas may not flow as well.

Tip: Talk to an expert before you choose black steel pipes for big jobs. You need to check if the pipes fit with other parts and think about how much care they will need later.

Here is a table that shows the main good and bad points of black steel pipes:

| Aspect | Pros | Cons |

|---|---|---|

| Strength & Durability | High hardness and strength; suitable for high temperature and pressure | Susceptible to corrosion if oxide layer is damaged; needs regular maintenance |

| Cost-effectiveness | Affordable material; simple production process | Heavier than PVC or aluminum; increases handling and support costs |

| Fire Resistance | High melting point; good for fire sprinkler systems | Rough inner surface reduces flow efficiency; increases energy use and sediment buildup |

| Installation | Easy to bend, cut, and connect by welding or threading | Inner surface roughness can cause blockages and higher maintenance needs |

| Corrosion Resistance | Protective oxide layer offers some resistance | Oxide layer easily damaged in humid or corrosive environments; leads to corrosion risks |

Pros:

Very strong and lasts a long time

Saves money for many jobs

Black coating helps stop rust

Comes in different sizes

Cons:

Coating can come off and let pipe rust

Not as bendy as other pipes

Does not fit with every part

Black steel pipes last longer than black iron pipes, even if they cost more at first. They need fewer repairs, so they are a good choice for jobs that need strong pipes. Stainless steel pipe does not rust as much and needs less care, but it costs more. Builders should think about these things before picking which pipe to use.

Black steel pipes and stainless steel pipes are used in different ways. They have different strengths, costs, and how much care they need. These things decide where each pipe works best.

| Attribute | Black Steel Pipes | Stainless Steel Pipes |

|---|---|---|

| Durability | Strong and durable for high-pressure use | Highly durable, ideal for high-pressure and high-temperature environments |

| Corrosion Resistance | Prone to corrosion; needs coatings | Excellent corrosion resistance due to chromium alloy |

| Maintenance | Needs frequent checks and repairs | Low maintenance; easy to clean and maintain |

| Typical Applications | Gas lines, fire sprinkler systems, heating | Food and beverage processing, pharmaceutical manufacturing, water systems, chemical processing, oil and gas industry, energy and power generation |

Black steel pipes are used for oil and gas jobs. They also work in heating and fire sprinkler systems. These pipes can handle lots of pressure and heat. They move oil, steam, and air. They cost less, so factories like to use them. But black steel pipes need more care to stop rust, especially with water.

Stainless steel pipes do not rust easily and last a long time. They have chromium that protects them from rust. These pipes are used in food factories, medicine making, chemical plants, and water systems. Stainless steel pipes are also used for oil and gas, energy, and power. Their smooth surface makes cleaning simple, which is good for places that need to stay clean.

Industries pick stainless steel pipes to move oil, water, and chemicals. Cleanliness and safety are important in these jobs. Food factories use food-grade stainless steel pipes to keep things clean. Medicine factories use stainless steel pipes to move fluids and gases safely. Water and chemical plants use stainless steel pipes because they last long and work in tough places.

Stainless steel pipes are best where rust is a big problem, cleaning is needed, and hygiene rules are strict. Black steel pipes are cheaper and good for high-pressure gas and heating, but stainless steel pipes are better when strength and cleanliness matter most.

Black steel pipes are used in many jobs because they are strong and not too expensive. Builders and engineers pick them for lots of important uses.

Gas and oil pipelines need strong pipes to move things far. Black steel pipes are tough and last a long time.

People use black steel pipes in homes for gas lines and heating. These pipes can handle high pressure, so they are a good choice.

In building work, black steel pipes help hold up heavy things. They do not bend easily and are good for frames.

Power plants use black steel pipes to move steam and cool things down. The pipes work well under high pressure.

Scaffolding and temporary buildings use black steel pipes. These pipes are easy to put together and take apart.

Factories and farms use these pipes to move materials and water. They also help support machines.

| Industry Sector | Key Applications of Steel Pipes (including Black Steel Pipes) |

|---|---|

| Construction | Plumbing, electrical systems, structural support in commercial and residential buildings |

| Power Plants | Cooling systems, steam and fluid transport, structural support under high pressure/temperature |

| Water and Sewer | Transport of potable water and wastewater, corrosion-resistant pipelines |

| Manufacturing | Transport of raw materials, cooling systems, structural support in high-pressure environments |

| Oil and Gas | Drilling operations, gathering lines, trunk lines for safe transport of oil and gas |

| Shipbuilding | Ship hull construction, internal plumbing, electrical, and HVAC systems |

| Textile Industry | Machinery and equipment handling high pressure and corrosive chemicals |

| Agricultural Industry | Irrigation systems, machinery, structural fittings with carbon-mixed steel pipes |

Tip: Black steel pipes are strong and not costly. This makes them great for big projects where saving money is important.

Stainless steel pipes are best when you need pipes that do not rust and must stay clean. Project managers should use these pipes in these cases:

Some jobs need pipes that do not rust, like in chemical plants or food factories.

Pipes in wet or salty places, like near the ocean, need to fight rust. Stainless steel pipes work well there.

Some places, like food and medicine factories, need very clean pipes.

Projects that need pipes to handle very hot or cold things should use stainless steel pipes.

Stainless steel pipes cost more at first but need less fixing later. This saves money over time.

If a project cares about the environment, stainless steel pipes are good because they can be recycled.

If pipes will be seen and need to look nice, stainless steel pipes have a smooth, shiny look.

Stainless steel pipes are also good for plumbing when clean water is needed. Their smooth inside stops dirt from building up and makes cleaning simple. Many companies pick stainless steel pipes because they work well in hard jobs.

Note: Stainless steel pipes cost more at the start but save money later because they do not need many repairs or to be replaced often.

Black steel pipes are strong and save money. They work well for oil, gas, and fire safety jobs. Stainless steel pipes do not rust easily. They last a long time and need little care. People should pick pipes that fit the job, cost, and place.

Black steel pipes are good for jobs with high pressure.

Stainless steel pipes are best where it is wet, clean, or very hot.

Experts say to look at rules, how pipes will be used, and total costs before choosing which pipe to use.

Black steel pipe does not resist rust well. Stainless steel pipe contains chromium, which protects it from corrosion. Stainless steel pipe works better in wet or harsh environments.

No. Black steel pipe can rust and release iron oxide into water. Stainless steel pipe is safer for drinking water because it does not corrode easily.

Builders pick black steel pipe for gas lines because it is strong and cost-effective. It handles high pressure well. Stainless steel pipe costs more, so black steel pipe saves money in many gas projects.

Experts recommend checking black steel pipes every year. Regular checks help find rust early. Stainless steel pipe needs fewer inspections because it resists corrosion.

Yes. Stainless steel pipe resists weather and moisture. It lasts longer outside than black steel pipe. Stainless steel pipe is a good choice for outdoor plumbing and exposed systems.