Views: 0 Author: Site Editor Publish Time: 2025-08-30 Origin: Site

Stainless steel pipe is important in many industries. It lasts a long time and does not rust easily. It can be used in many ways. These pipes are used in oil and gas, chemical processing, and building. They work well in tough places. Picking the right grade helps the pipe work better and last longer. Asia-Pacific uses the most pipes. This is because factories and buildings need them.

| Metric | Value |

|---|---|

| Stainless steel market size (2024) | USD 126.36 billion |

| Projected market size (2030) | USD 197.29 billion |

| CAGR (2024-2030) | 6.7% |

Stainless steel pipes have many grades. Each grade is made for a special job. Some grades stop rust. Some handle heat. Others can take a lot of pressure. Picking the right grade makes pipes stronger. It also helps them last longer and saves money. Many industries use these pipes. Oil, chemical, construction, and food processing all use them. Stainless steel pipes do not rust easily. They last longer than other pipes. This makes them good for hard places. They work well in marine areas, power plants, and hospitals. Seamless pipes are even stronger. They are very reliable. They are best for high pressure or heat. If you follow the rules and take care of the pipes, they stay safe. They also stay clean and work well for a long time.

Stainless steel pipes have many grades and types. Each grade is made for a special job. Picking the right grade helps the pipe work well. Some pipes face high heat, strong chemicals, or heavy pressure. Knowing about the grades helps people choose the best pipe.

There are five main grades of stainless steel pipes. These are austenitic, ferritic, martensitic, duplex, and precipitation hardening. Each grade has its own chemical and mechanical features. This makes each grade good for different uses.

Austenitic Stainless Steel Pipe (300 Series)

Grades like ss 304 pipes, ss 316 pipes, ss 317 pipes, 310, and 321 are in this group.

These grades have lots of chromium and nickel. For example, ss 304 pipes have 18% chromium and 8-10% nickel. This makes them resist rust and easy to weld.

ss 316 pipes have 2-3% molybdenum. This helps them fight damage from salt water. They are great for marine and chemical jobs.

ss 317 pipes can handle high heat and sulfuric acid. They are used in chemical plants.

Austenitic grades do not attract magnets when heated. They stay strong even when hot.

Ferritic Stainless Steel Pipe (400 Series)

Grades like 409 and 430 are common.

Ferritic stainless steel pipe has 12-18% chromium and little carbon. These pipes are magnetic and cost less.

They resist rust a bit and are easy to shape. But they break easier and do not handle heat as well as austenitic types.

Martensitic Stainless Steel Pipe

Grades like 410 and 420 are used often.

Martensitic grades are very hard and tough after heating. But they do not resist rust as well as austenitic or duplex grades.

These pipes are magnetic and can be made harder with heat. They are good when strength and toughness matter.

Duplex Stainless Steel Pipe

Grades like 2205 and 2507 mix the best parts of austenitic and ferritic types.

Duplex stainless steel pipe is very strong and hard. It resists pitting, crevice rust, and cracking from stress.

These grades are used in tough places like oil platforms and chemical plants.

Precipitation Hardening Stainless Steel Pipe

Grade 630, called 17-4 PH, is a popular type.

This grade gets very hard and handles heat well. It is used for airplanes, medical tools, and valves.

Precipitation hardening grades get strong with heat and resist rust fairly well.

Tip: Seamless pipes and welded pipes are chosen based on grade and use. Seamless pipes are strong and even. They are best for high pressure or heat.

The table below shows the five main types of stainless steel pipes. It lists how well they resist rust and how strong they are:

| Metallurgical Type | Corrosion Resistance | Mechanical Strength and Other Properties |

|---|---|---|

| Austenitic (e.g., 304, 316, 317) | Great at resisting rust; 316 is better in salty water because of molybdenum. | Strong even when hot; not magnetic. |

| Ferritic (e.g., 409, 430) | Not as good at resisting rust as austenitic; good against chloride cracking. | Magnetic; breaks easier; cannot be made harder with heat; easy to shape but not good with heat. |

| Martensitic (e.g., 410, 420) | Okay at resisting rust; very strong after heating. | Magnetic; can be made harder with heat; strong. |

| Duplex (e.g., 2205, 2507) | Very good at resisting rust, pitting, and cracking; great against stress cracking. | Stronger than austenitic and ferritic types; easy to weld; used in tough places. |

| Precipitation Hardening (e.g., 17-4 PH) | Okay to great at resisting rust, depends on mix. | Very strong because of hardening; often magnetic. |

Choosing the right stainless steel pipe grade depends on many things. Each job needs something special. The place where the pipe will be used matters a lot.

Corrosion Resistance

ss 304 pipes are used for many jobs because they resist rust and cost less.

ss 316 pipes are picked for marine, chemical, and medicine jobs. They fight pitting and crevice rust, especially in salty places.

duplex stainless steel pipe resists rust even more. It is used for oil rigs, water plants, and chemical tanks.

Mechanical Strength and Durability

Jobs that need strong pipes, like supports or high-pressure seamless pipes, use duplex stainless steel pipe or martensitic grades.

Precipitation hardening stainless steel pipe is used for airplanes and medical tools. These jobs need both strength and heat resistance.

Environmental Conditions

Ferritic stainless steel pipe works well where rust is not a big problem and cost matters.

Austenitic grades, like ss 304 pipes and ss 317 pipes, handle heat and strong chemicals. They are used for food, heat exchangers, and chemical plants.

Cost Considerations

Prices for stainless steel pipe grades are very different. ss 304 pipes cost the least. Duplex and precipitation hardening grades cost more because they work better.

For example, a 1" Sch 40 ss 304 pipe costs $3.50–$12.00 per foot. A 2" Sch 80 ss 316 pipe costs $7.00–$20.00 per foot. Duplex grades can cost over $40.00 per foot for top brands.

Even though better grades cost more at first, they last longer and need less fixing. This saves money over time compared to carbon steel or plastic pipes.

Industry Standards and Compliance

Most jobs need stainless steel pipes to meet strict astm rules. These rules cover what the pipe is made of, how strong it is, and how it is tested.

astm rules make sure seamless pipes and welded pipes are safe and work well in tough places.

Other rules like DIN, GB, and JIS also help control how stainless steel pipes are made and checked.

Fabrication and Welding

Some jobs need pipes that are easy to weld and shape. Low carbon types like 304L and 316L are best to stop rust after welding.

Seamless pipes are picked for important jobs where evenness and strength matter most.

Customer Preferences and Aesthetics

The look of the pipe, shiny or dull, and if it is magnetic, can affect which grade is picked.

Following astm and other rules makes sure pipes meet what customers want for quality and how they work.

Note: When picking stainless steel pipe grades, engineers must think about the job now and later. They should look at fixing, cost over time, and rules.

The many grades of stainless steel pipe give industries safe and strong choices. By learning about each grade and type, buyers can pick pipes that save money and work well. Seamless pipes are extra strong and reliable. They are used for important jobs in oil and gas, chemical plants, and power stations.

Stainless steel pipes are used in tough places. They do not rust easily and last a long time. Many industries pick them because they are strong. Engineers choose special grades for each job. This keeps people safe and helps pipes last longer. Below are some main uses and reasons why stainless steel pipe is a good choice.

Chemical plants need pipes that can handle strong chemicals and heat. Stainless steel pipe does not get damaged by acids or alkalis. Grades like 316 and duplex types fight rust better, especially with chloride ions around. Pipes can crack or get pits when stressed and exposed to harsh chemicals. Checking pipes often and following astm rules helps stop problems. In geothermal plants, cracked tubes showed that chloride and bad heat treatment made cracking worse. Picking the right grade and making pipes the right way is important.

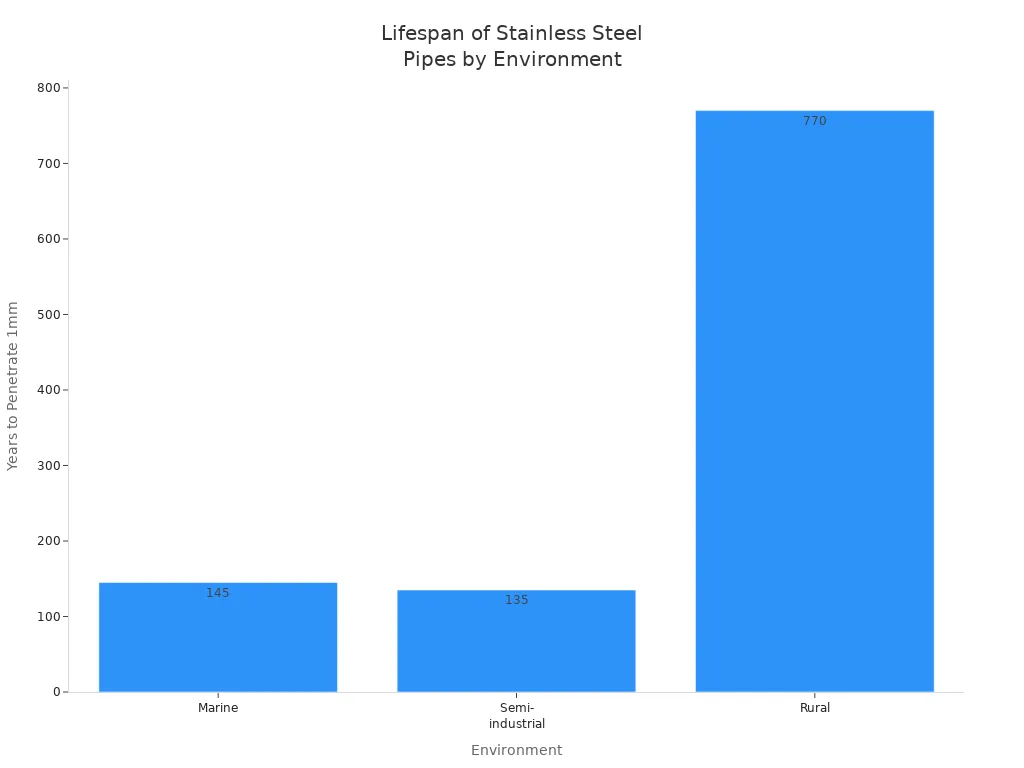

Oil and gas jobs need pipes that handle high pressure and heat. Stainless steel pipes are strong and do not rust easily. A chromium oxide layer protects pipes from things like sulphur and naphthenic acid. Seamless pipes are used to move oil and gas under high pressure. Workers like stainless steel pipe because it lasts long and is easy to clean. Oil pipelines can last 30 to 50 years. With good care and checks, stainless steel pipes can last even longer. The table below shows how long it takes for grade 304 stainless steel to rust in different places:

| Environment | Estimated Time to Penetrate 1mm (Years) for Grade 304 Stainless Steel |

|---|---|

| Marine | 145 |

| Semi-industrial | 135 |

| Rural | 770 |

Power plants use stainless steel pipes for steam, water, and fuel. These pipes must handle high heat and pressure. The grade picked depends on how hot or cold it gets. For example, 304 stainless steel pipes work from -196°C to 800°C. 316 pipes can go up to 1000°C. Higher grades like 316L have more chromium, nickel, and molybdenum. This helps stop rust and pitting. Seamless pipes are used for important systems to keep things safe. Following astm rules makes sure pipes work well and are safe. Cleaning and checking pipes often helps them last longer and work better.

Stainless steel pipes are important in building today. They are picked for many projects because they work well and look nice. These pipes help hold up buildings and also make them look better.

Builders use stainless steel pipes to support big things like buildings and bridges. These pipes are strong and can bend without breaking. They hold up heavy things and can move a little without damage. This makes them good for frames, columns, and trusses. Stainless steel pipes do not get ruined by bad weather. This helps buildings last longer outside. Many architects like these pipes because they are safe and look modern.

Note: Rules like ASTM, EN, and DIN make sure stainless steel pipes are safe and good quality for building.

Stainless steel pipes help keep water clean in homes and factories. Their smooth surface stops germs from growing. This keeps water safe to drink. The chromium-rich oxide layer keeps the pipes from rusting. This means water pipes work well for many years. Grade 304 pipes can last up to 70 years. Grade 316 pipes can last over 100 years in hard places. These pipes can handle high pressure and hot or cold water. They do not leak or break easily. Even though they cost more at first, they last a long time and do not need much fixing.

Architects pick stainless steel pipes for handrails and decorations. These pipes look shiny and do not rust. They make stairs, balconies, and public places look nice. Stainless steel pipes are strong and safe for people to use often. They stay looking good even outside in the rain or sun. This makes them great for both inside and outside designs.

Stainless steel pipes give buildings strength and style.

They are used for frames, water pipes, and decorations.

Builders like these pipes because they are strong and last a long time.

Stainless Steel Pipe is very important in food and drink factories. Workers pick grades 304 and 316 because they do not rust and are clean. Grade 316 protects better against salty foods and drinks. The smooth surface of Stainless Steel Pipe stops bacteria from growing. It also makes cleaning much easier. Plant managers trust these pipes because they follow FDA and world safety rules.

Engineers use special designs for Stainless Steel Pipe in food plants. They make sure there are no hidden spots where germs can hide. Pipes drain fully to stop contamination. Sanitary parts help keep the system safe. The chromium layer on Stainless Steel Pipe heals itself. It stops rust and keeps bacteria out of cracks.

Workers use Clean-in-Place systems to wash the pipes. This cleans the pipes without taking them apart. Electrochemical polishing makes the pipe even smoother. This helps stop bacteria from sticking. Picking the right size, thickness, and finish keeps the system safe and working well.

Main hygiene and safety needs for Stainless Steel Pipe in food and drink factories:

Use grades 304 and 316 for rust protection and cleanliness

Smooth surfaces stop bacteria and help cleaning

Must follow FDA and other safety rules

Good design avoids hidden spots and lets pipes drain fully

Sanitary parts stop contamination

Handles hot and cold jobs

Food and drink factories use Stainless Steel Pipe for making products. The pipes do not react with food or drinks. Smooth pipes stop germs from sticking and can handle hot or cold temperatures. Pipes are sloped so liquids drain out and do not sit still. Factory layouts and pipe paths help stop bacteria and keep things moving.

Stainless Steel Pipe works with Clean-in-Place and Steam-in-Place cleaning. These ways keep pipes clean without taking them apart. The pipes follow FDA and WHO rules for safe food making. Surfaces that touch food are smooth and easy to check.

Common things about Stainless Steel Pipe in processing lines:

Does not react with food or drinks

Smooth and easy to clean

Works in hot and cold places

Supports CIP and SIP cleaning

Follows world safety rules

People who make medical tools use Stainless Steel Pipe to stop contamination. The chromium layer protects pipes from rust and makes cleaning simple. Grades like 304 and 316 work in different places. Special factories use their own tools and racks to keep pipes clean.

Teams install pipes by following strict steps. They talk with users about keeping pipes safe from germs. Cleaning and fixing pipes often stops rust and contamination. Using the right parts together helps avoid damage from mixing metals.

Rules like FDA, USP Class VI, and ISO 2852:1993 say Stainless Steel Pipe must keep things sterile and easy to track. Makers use clamp connections and 316L stainless steel for strong and clean pipes. Certifications and tracking are important for every product.

Stainless Steel Pipe is good for medical tools because:

It does not rust and is easy to clean

The surface does not react or let germs in

Helps keep factories sterile

Follows strict safety rules

Easy to track and certify

Stainless Steel Pipe keeps food, drinks, and medical tools safe. Its clean surface, strength, and world safety rules make it the best choice for important jobs.

Shipbuilders use Stainless Steel Pipe for many ship parts. These pipes do not rust in saltwater, so ships last longer. Marine-grade stainless steel, like grade 316, has molybdenum. This helps stop pitting and cracking from seawater. Super duplex stainless steel makes pipes lighter and fewer are needed. This helps ships weigh less and work better. A study from the University of Manchester showed super duplex stainless steel cuts pipe weight by 15%. It also lowers the number of pipes by 38% compared to cupro-nickel alloys.

Stainless Steel Pipe is used in desalination, cooling, ballast, and firewater systems. Shipbuilders also use these pipes for hinges, shafts, railings, and fasteners. Stainless steel takes the place of painted carbon steel pipes. This saves time and money because it does not need paint. Stainless Steel Pipe lasts a long time and does not rust. This means ships need less fixing and cost less to run.

Note: The sea is tough for Stainless Steel Pipe. High costs, price changes, and not enough raw materials can be problems. Pipes can crack from stress, rust from other metals, or from the air. Good design and coatings help stop these problems.

Common corrosion challenges in marine settings:

Cracking from chlorides and oxygen

Rust from different metals touching

Hydrogen damage from bad protection

Rust and pits under insulation

Car makers use Stainless Steel Pipe in exhausts and hydraulic lines. These pipes handle heat and bad gases. Stainless steel changed exhausts, making them last over eight years. Grades like 409, 439, and 304 have different looks and rust resistance. Grade 409 is used a lot for exhausts. Grade 304 is a top choice and is not magnetic.

Hydraulic systems in cars use Stainless Steel Pipe for steering and brakes. These pipes do not rust, take high pressure, and handle shaking. Careful making of pipes keeps cars safe and working well. Stainless Steel Pipe keeps the system strong, which is important for safe driving.

Main causes of pipe failure in marine and transportation sectors:

Cracking from seawater and wet air

Pulling forces from welding and use

Weather changes and heat cycles

Weak spots and bad design

Stainless Steel Pipe is strong, does not rust, and lasts a long time. It is picked for ships, cars, and hydraulic systems. Makers use these pipes to keep things safe, strong, and save money in hard places.

Stainless steel pipe is used in lots of industries. It is strong and lasts a long time. It does not rust easily. Picking the right grade keeps people safe. It also helps pipes last longer. New tools like smart sensors and 3D printing help make better pipes. Eco-friendly ways to make pipes are good for green buildings and clean energy. As technology gets better, stainless steel pipe will be even more important. It will help build safer and cleaner systems. It will also make things work better.

Stainless Steel Pipe does not rust like carbon steel pipe. It lasts longer and is strong. It works well in tough places. Many companies pick it because it is easy to clean. It also needs less fixing.

Grade 304 Stainless Steel Pipe is good for most water systems. It keeps water safe and does not rust much. Grade 316 Stainless Steel Pipe is better for salty water or where rust is a bigger problem.

Stainless Steel Pipe, mostly grade 316, can last more than 100 years in the sea. Molybdenum in the pipe helps stop saltwater from causing rust. Checking pipes often and putting them in right helps them last longer.

Food factories use Stainless Steel Pipe because it does not mix with food. Its smooth surface keeps bacteria away. Grades 304 and 316 are safe and meet FDA rules.

Makers think Stainless Steel Pipe is easy to weld and shape. Low-carbon grades like 304L and 316L are best for this. These grades stop rust after welding and work for many building jobs.